Custom Quote Request Form

Product Sleeves and Belly Bands

| FAQ's Specification Learn More Reviews | ||||||||||||

|

Q: What are product sleeves? A: A box sleeve is a cost-effective packaging solution that is often used in place of or in conjunction with product boxes. It can function as either primary packaging when used to encase the product or as secondary packaging when it is slid over a closed product box. Product sleeves provide additional space for branding and informational content and enhance the unboxing experience. A thoughtfully designed product sleeve improves the visual appeal and makes a lasting impression on consumers. Q: What are belly bands and are they different from product sleeves? A: A belly band is a type of product sleeve. These bands typically wrap around the middle of products and product boxes. Belly bands perform dual functions by keeping the products secure while providing additional branding space. The terms, packaging sleeves and belly bands, are often used interchangeably. The main difference is that while belly bands cover only a portion of the product, leaving the sides visible, product sleeves fully encase the product and cover all sides completely. Additionally, belly bands generally do not have any creases or fold lines as they are often used to wrap softer products like clothing or blankets. Q: What benefits do sleeves offer compared to product boxes? A: Compared to regular product boxes, sleeves and belly bands are more versatile and provide unique benefits including:

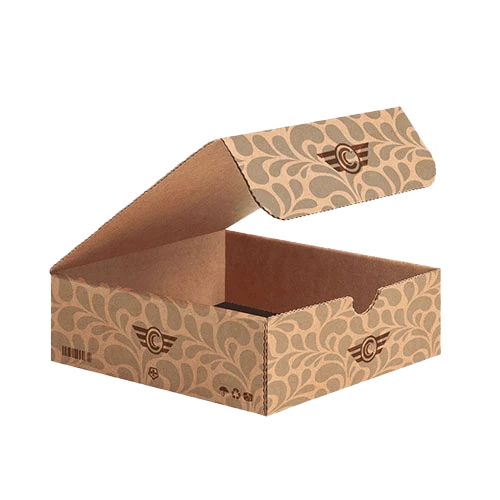

Q: What are some examples of typical uses for sleeves and belly bands? A: Cardboard sleeves are incredibly versatile and suitable for packaging a wide range of products, including food containers, soaps, books, electronics, candles, cosmetics, apparel, and various other retail items. Sleeves come in handy for deploying multiple packaging finishes while maintaining a consistent look for the primary packaging design. Q: Are product sleeves able to incorporate perforations, adhesive closures, or tear strips? A: Yes, sleeves can incorporate perforations, adhesive closures, or tear strips. These features can help enhance overall packaging by making it easier for customers to open it while also providing additional security and protection for the contents inside. In particular, perforation lines allow for easy tearing, adhesive closures offer resealability, and tear strips facilitate quick access to enclosed products. Q: How can I determine the right size for product sleeves? A: To achieve the best fit for your product or box, it is important to provide accurate external measurements of the box length, width, and height. In addition, you will need to decide on how much of the box area do you want to cover with the sleeve. Once you share these dimensions with us, our team can assist in finalizing the sleeve dimensions to ensure a snug yet easily removable sleeve fit. Q: What materials are used for manufacturing cardboard sleeves? A: You have the option to select from a wide range of materials, including kraft card, premium white cardstock, corrugated board, and textured or uncoated cards. These material choices are offered in various thicknesses to align with your project specifications. You can also opt for custom shapes and features such as foil stamping, embossing, and metallic inks to give your products a competitive edge. Q: What form are product sleeves delivered in? A: Product sleeves come pre-creased. You can choose pre-glued sleeves for immediate use or those with self-adhesive tape for easy assembly. We also offer interlocking sleeves that are pre-creased and shipped flat. These sleeve ends are closed with the help of interlocking tabs that eliminate the need for glue or adhesive tape.

Custom Packaging SleevesFrom providing additional branding space to offering functional benefits such as product protection and evidence of tampering, custom-printed product sleeves and belly bands can help enhance product presentation and grab consumer attention. Product sleeves are ideal for items that either can be sold without any packaging or come in their own generic packaging. Soaps, fruits in plastic containers, pre-packaged cookies, tool sets, and clothing items are just some of the many products that are often packaged and branded using custom belly bands to elevate product presentation, improve brand visibility, and engage consumers on a deeper level. How do Product Sleeves Work?Custom packaging sleeves are typically shipped flat with a self-adhesive double-sided tape on one end of each sleeve. In order to apply the belly bands or sleeves to a product, the bands are wrapped around the underlying product packaging and the two sleeve ends are then sealed together with the help of the double-sided tape. Product sleeves can be made in custom sizes using a wide variety of different materials in order to have the required coverage area and durability. Benefits of Product Sleeves and Belly Bands:This versatile packaging solution offers many benefits, from additional branding opportunities to functional advantages, including:

Usage of Product Sleeves and Belly Bands:From conveying product information and enhancing shelf presence to creating memorable unboxing experiences, using product sleeves and belly bands opens up creative possibilities for product manufacturers and retailers looking to elevate their packaging. Prominent benefits include:

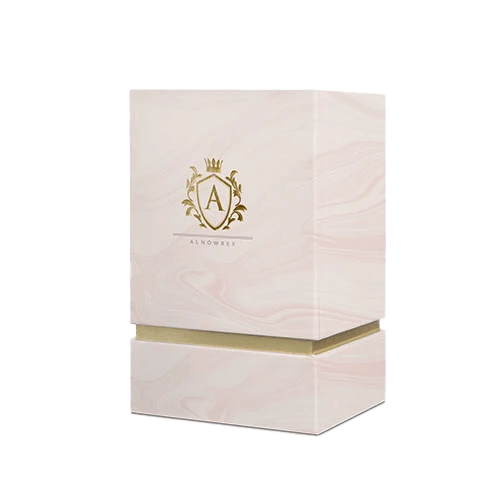

Product sleeves complement various box styles, enhancing their functionality and visual appeal. When paired with lightweight folding carton boxes, sleeves offer additional branding space and product protection, creating a sophisticated packaging presentation. Similarly, when combined with premium finish rigid boxes or magnetic closure boxes, sleeves can add a layer of elegance and customization, elevating the overall packaging experience. Additionally, sleeves enhance the unboxing experience of custom corrugated mailer boxes by providing an extra layer of branding. By incorporating product sleeves that wrap around transparent clamshell packaging, product manufacturers can add an additional layer of branding and product information without obstructing the product view. In conclusion, these sleeves offer many benefits and creative possibilities for brands looking to elevate their packaging design. Whether used for branding, protection, or promotional purposes, these versatile packaging sleeves can help in making a lasting impression on consumers and enhance overall consumer experience. |